What we do

We help industries operate more efficiently.

Rooted in a long-standing family legacy in industrial air pollution control, we’ve developed proprietary technologies that allow us to guarantee performance for our custom-engineered separation systems.

Our team provides system audits to identify performance gaps and in-depth troubleshooting to ensure lasting, sustainable results. As a multi-industry R&D and process development partner, we serve chemical, refining, pharmaceutical, bio-energy, and other complex sectors.

We keep industries running strong.

Beyond air emissions and recovery solutions, we support regional infrastructure with precision-engineered and fabricated parts, assemblies, and essential support components, including tailored access systems and structural elements.

Our ASME-certified sheet metal fabrication shop specializes in pressure-rated and severe-duty vessels, offering advanced finishing techniques for handling sensitive and abrasive materials.

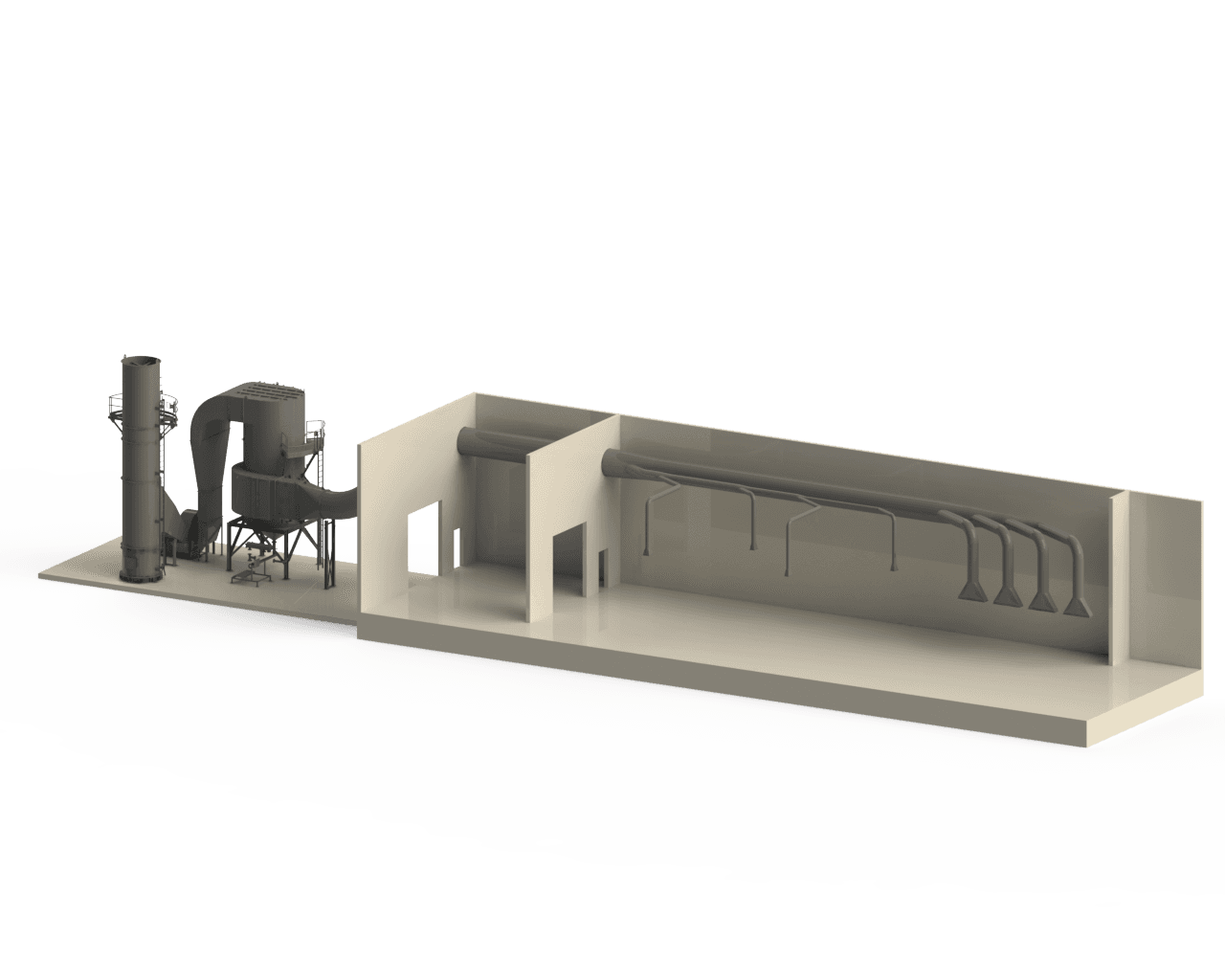

Our Work in Action

You’re in Good Company

Our Impact

I am pleased to recommend Heumann Environmental for their exceptional work in the design, fabrication, and optimization of cyclone separators and related gas-solid classification equipment. Throughout our collaboration, Heumann Environmental has consistently demonstrated deep technical expertise, professionalism, and a commitment to quality that distinguishes them in the field of particle separation and gas cleaning. Read more

I have worked with Heumann Environmental since its inception and with Bill Heumann long before that. Heumann Environmental is my top choice for recommending cyclones and filters. They have a firm grasp of aerodynamic design principles, multiphase flow behavior, and materials selection, all of which are critical for achieving high-efficiency separation while minimizing pressure drop. Notably, their ability to customize cyclone designs to meet specific process conditions—such as particle size distribution, gas composition, temperature, particle attrition management, and erosion mitigation—is impressive. When I recommend Heumann Environmental, I know effective solutions will be delivered promptly.

Their customer service also exceeds industry norms. Heumann Environmental is recognized for its responsiveness, integrity, and attention to client needs. From conceptual design through commissioning, they provide transparent communication and thoughtful engineering support, ensuring each system integrates well and maintains long-term reliability.

I wholeheartedly endorse Heumann Environmental to any of my clients. Their commitment to innovation and client success continues to make them a trusted partner in achieving my

business objectives.

Raymond A. Cocco

President

Particles in Motion, LLC

Working with Heumann Environmental has saved our company $70MM in lost profit over the last 8 years by eliminating production downtime. Bill and his team do an amazing job developing the right solution for particle filtration, ejectors, and cyclones. Based on the success of multiple projects, our working with relationship with Heumann has continued to grow and they are the main company we work with for our filtration improvement projects. Read more

One of things that sets Heumann apart is their high level of customer service. On several of our capital projects, Heumann was able to meet extremely tight deadlines to ensure equipment was installed in time for our planned turnaround. The professional service and customer first culture has resulted in Heumann receiving a high level of compliments from unit operations, capital projects, equipment inspections, and my company’s leadership team. Bill and his team’s level of support is second to none.

Back in 2016, Heuman worked with us to develop an innovative redesign of a critical ejector on one of our production units. The improved ejector was so successful, we have installed this new design on all our units.

On one of our more challenging bag house filters, we had worked with multiple vendors to resolve the issue with no success. We turned to Heumann to see if they could help us. Bill was able to quickly design a cyclofilter that has resulted in being a major process improvement for the manufacturing unit. Prior to installation of this new cyclofilter, the unit was experiencing a reactor outage every 4 months because of filter failures. Following the installation of the Heumann designed cyclofilter, we have had zero days of down time due to this filter in over 6 years of service.

Jeff Lowell

Engineering Fellow – PE Production

We want to help you operate more efficiently.

Whether you need custom-engineered air pollution control systems, high-performance fabrication, or expert troubleshooting, our team is ready to help you operate at peak efficiency—sustainably.