Inlet and Outlet Cyclone Geometry

At the heart of cyclone efficiency lies inlet and outlet configurations—pivotal elements that directly influence performance and durability. Here at Heumann Environmental, we collaborate closely with you to identify and recommend the ideal geometric configurations tailored to your specific application.

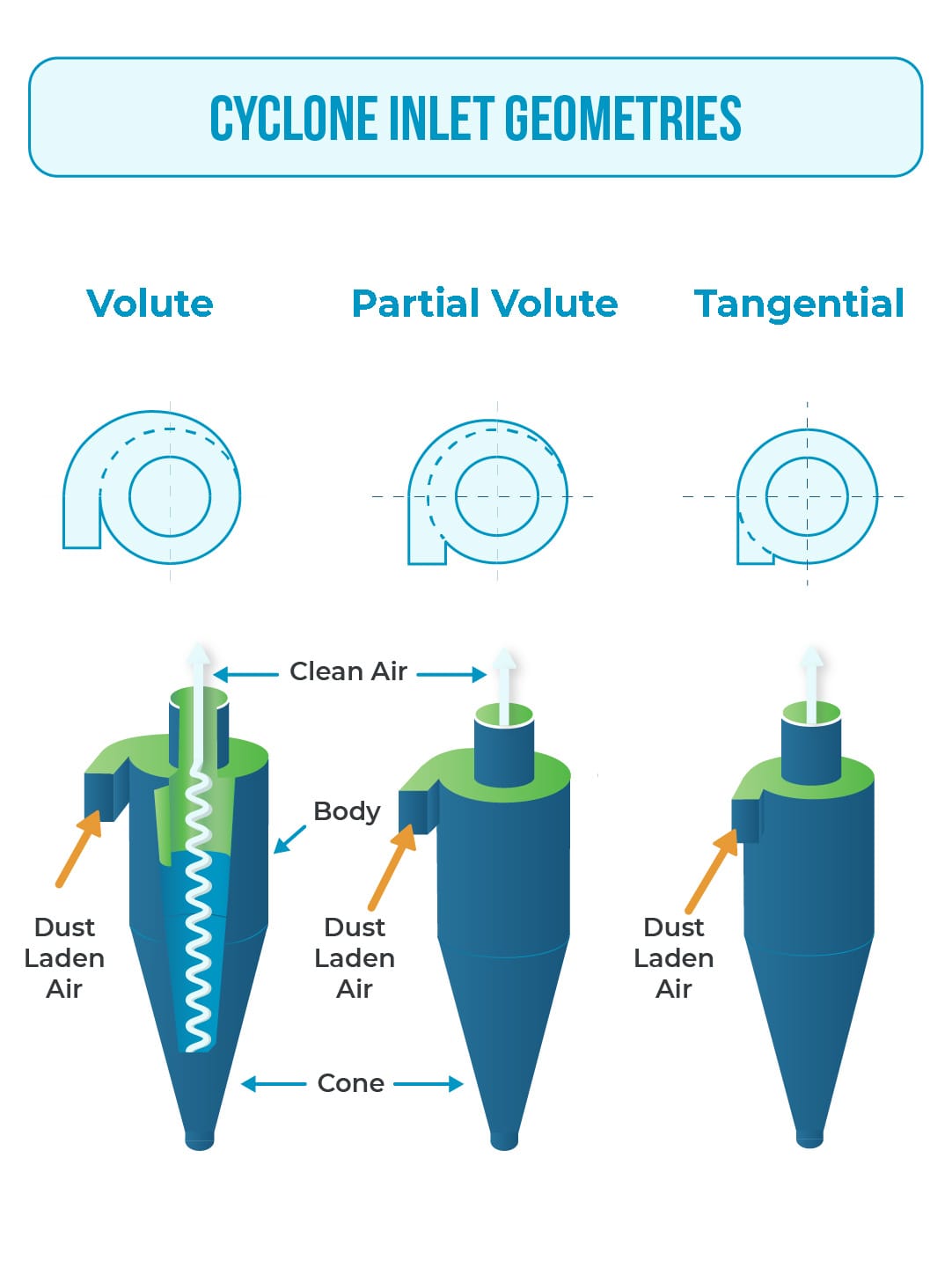

Inlet Geometry Options

Inlet design is critical to cyclone efficiency because the stronger the centrifugal force, the better the collection performance. This force is generated by converting straight-line (linear) airflow from a pipe or duct into a spinning (rotational) motion, a transition that happens right at or just behind the inlet.

Heumann Environmental offers three distinct inlet configurations, each engineered to optimize airflow and performance. Identifying the ideal design for the air pollution control process prevents common cyclone issues such as particle buildup and inlet wrapper erosion.

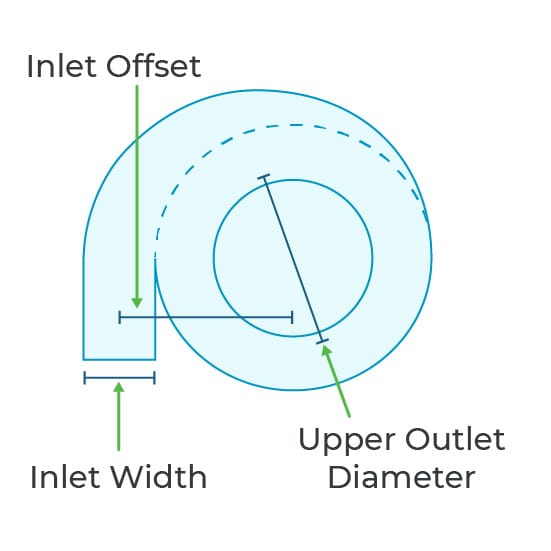

In a tangential inlet, the outer wall of the inlet is tangent to the body cylinder, so the inlet is fully inside the width of the body. Tangential inlets boast ease of fabrication and reduced material usage, making them ideal for larger cyclones with lower particulate loads. However, caution is advised at higher particulate levels, as the high tangential gas velocity at the inlet can accelerate wear and tear on the cyclone.

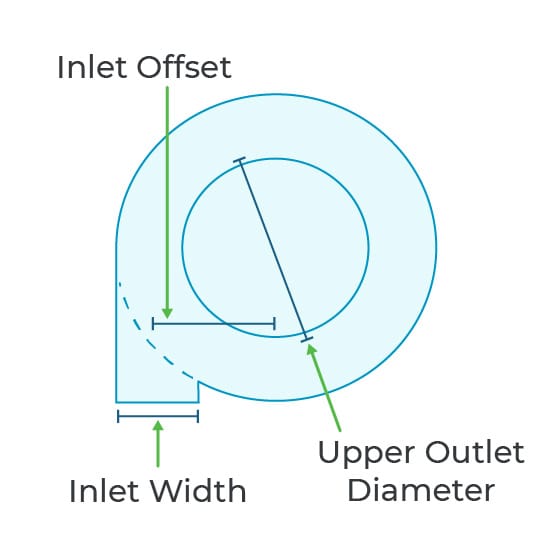

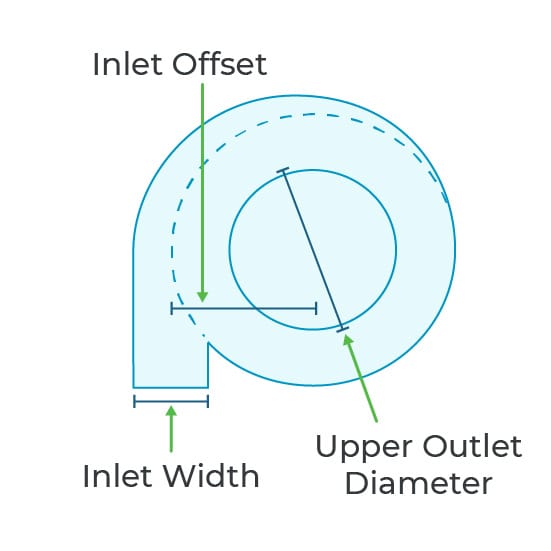

In a volute inlet, the inner wall of the inlet is tangent to (or fully outside of) the body cylinder and the inlet curves in to match the cyclone body diameter 180° from the point of entry. Volute inlets are preferred for higher efficiency cyclones, as the body diameter does not have to be large enough to accommodate the inlet’s width. This can lead to more efficient particle separation at the cost of increased pressure drop. Nevertheless, by slightly reducing the tangential velocity of the process gas, its design aids in minimizing wear and tear on the inlet wrapper of the cyclone at higher particulate loading .

Combining attributes of both tangential and volute designs, the partially volute inlet provides a balanced solution. Offering benefits akin to a volute setup without excessively elevating system pressure drop, this is the configuration we most often recommend.

Outlet Geometry Options

The size of the outlet pipe’s lower diameter plays a key role in cyclone performance. A smaller outlet diameter generally results in a higher pressure drop and improved particle collection efficiency.

Here’s why: As gas exits the cyclone, it continues to spin with the rotational momentum created by the inlet. When the outlet pipe’s diameter is reduced, the spinning vortex tightens, increasing centrifugal force. This boosts the chances that particles will be flung outward and separated before exiting the system.

A narrower outlet also lowers the vertical (axial) gas velocity, extending particle residence time and further enhancing separation. However, keep in mind, higher outlet velocities (caused by smaller diameters) will also increase pressure drop.

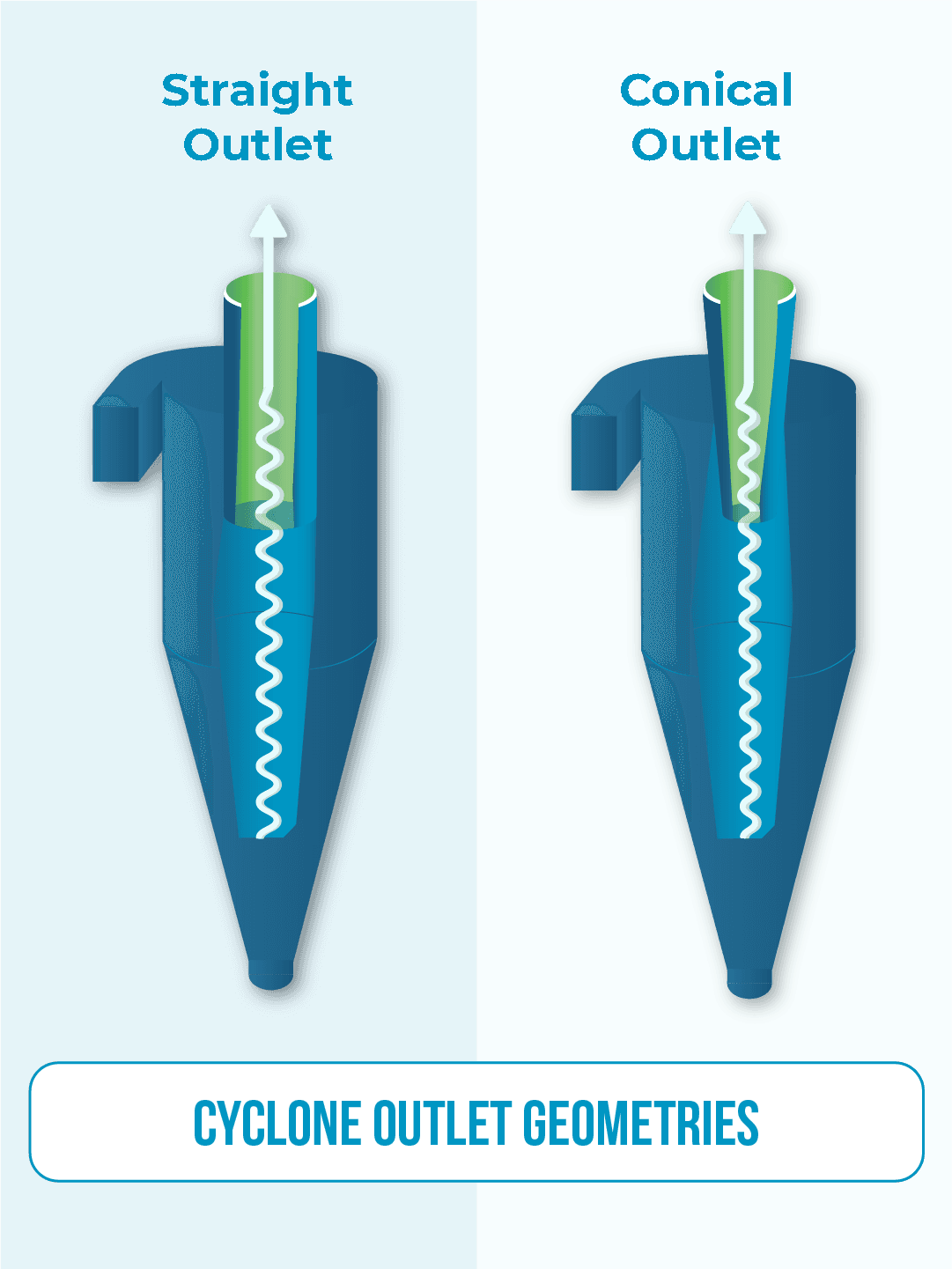

Heumann Environmental offers two distinct outlet configurations, each designed to meet specific performance goals.

As its name suggests, the straight outlet features a uniform diameter from bottom to top. This standard design works seamlessly across a wide range of applications, offering simplicity and reliability.

Engineered to optimize cyclone performance while minimizing pressure drop, the conical outlet is ideal for applications demanding maximum collection efficiency. Although its conical shape enhances performance, it is more complex to fabricate compared to a straight outlet.

Equipment Accessories & Options

While inlet and outlet configurations form the foundation of cyclone efficiency, complex operations require more.

Our comprehensive range of equipment options, including material enhancements, structural supports, and specialized components, lets you fine-tune your system for maximum durability, reduced downtime, and consistent performance. Explore the possibilities below.