Surface Finishes and Protection

In many applications, the condition of both the interior and exterior equipment surfaces post-fabrication holds immense importance. This is where the concept of “surface finish” comes into play, encompassing not only the smoothness of the metal but also the coatings and treatments applied to enhance its properties.

Understanding Surface Roughness

Surface roughness, inherent to all surfaces, is characterized by the presence of peaks and valleys (high and low points) on the metal’s surface. Quantifying this roughness is typically done through measuring the average roughness (Ra) within a specified area. Ra values are commonly expressed in micro-inches, with a smaller Ra indicating a smoother surface and a higher value suggesting heightened roughness.

Initially, metal leaves the manufacturing process with a “mill” finish, having an Ra reading of around 250 micro-inches. This “mill” finish serves as the industry standard for most equipment.

However, customers may require a surface finish that is smoother than “mill” to minimize the opportunity for material to stick to the equipment. This is particularly true for the interior surface but also applies to the exterior.

Mechanical Polishing for Smoother Surfaces

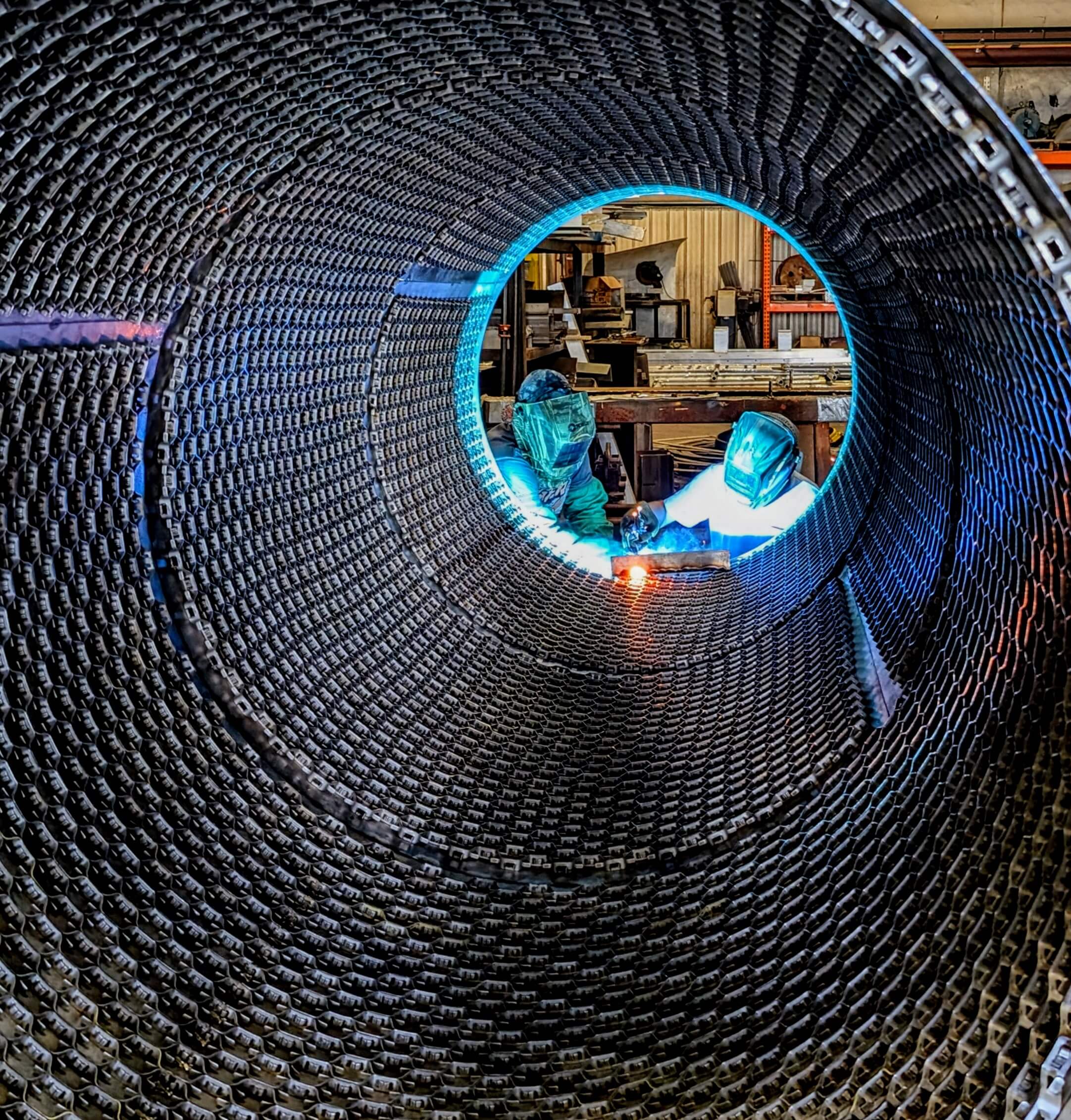

To attain a smoother surface than the mill finish, mechanical polishing is the most common approach. If the amount of area to be polished is large, it makes sense to send the plate to a company that specializes in polishing plate metal. This polishing would occur before cutting and forming. If the area to be polished is small, the polishing can be performed by hand.

While most of an equipment’s surface can be polished before cutting and forming, welds cannot. Welds must be polished by hand which becomes increasingly time-intensive as the desired Ra value decreases.

Meeting Specific Surface Finish Requirements

Certain applications, especially in the food, pharmaceutical, and nutraceutical industries, require ultra-smooth surface finishes, often in the 40–60 micro-inch range or less. These finishes are essential for ensuring purity, preventing contamination, and minimizing material loss. An ultra-high polish guarantees high cleanliness, minimal particle adherence, and compliance with stringent industry standards, all while simplifying maintenance and supporting product safety and quality. Achieving such high standards of polish is one of the areas where our expertise really shines.

Protecting Surfaces: Coatings and Treatments

After establishing the desired surface roughness, customers are tasked with a critical decision—how best to shield surfaces from internal process conditions and external environmental elements.

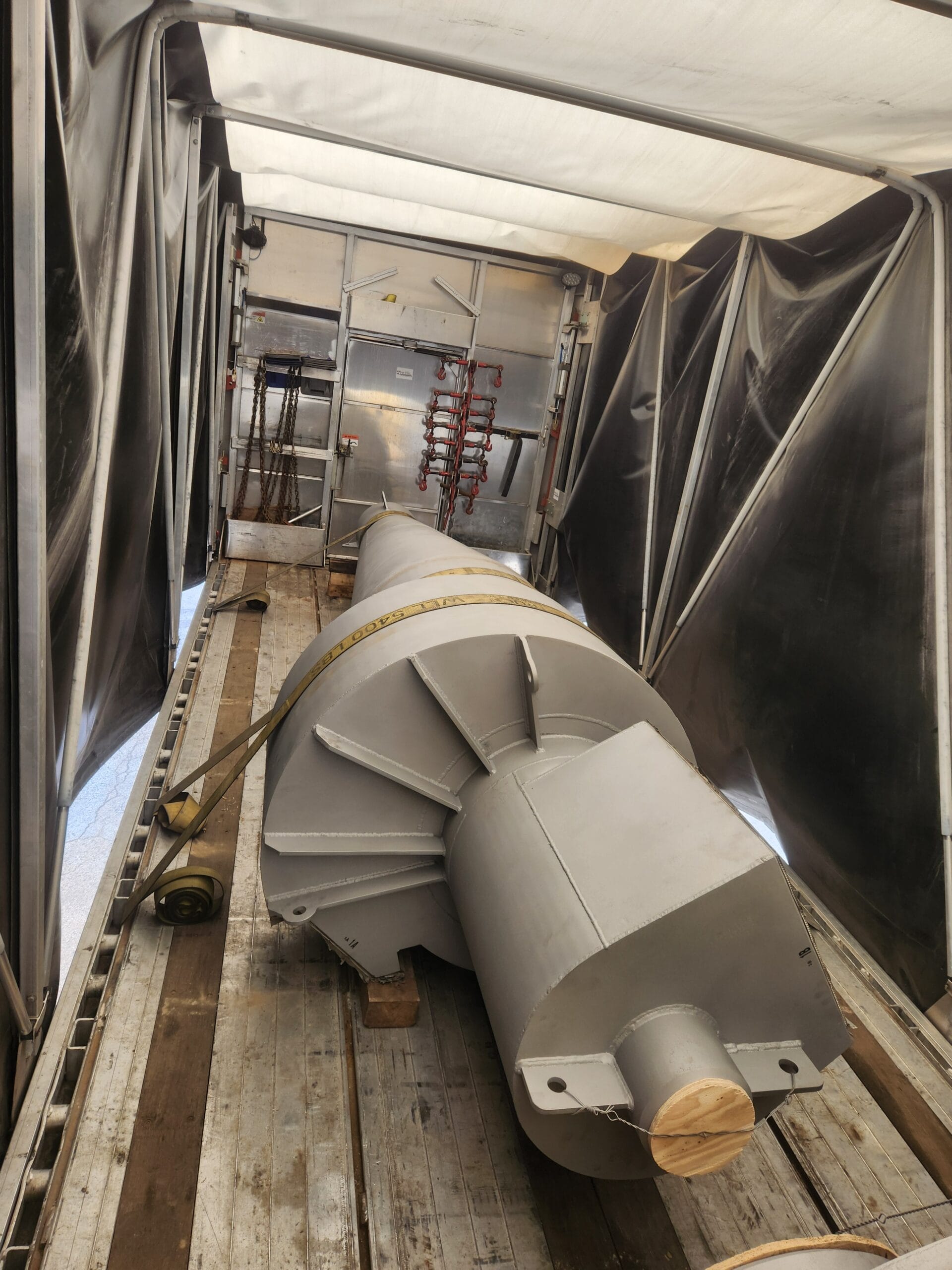

For carbon steel constructions, the standard practice typically involves applying at least one layer of external paint. This protective coating acts as a shield against corrosive elements and environmental wear, enhancing the longevity and resilience of the equipment.

In contrast, stainless steel exteriors commonly undergo acid washing, a process known as passivation. Passivation removes impurities and contaminants from the surface, promoting corrosion resistance and ensuring optimal performance over the equipment’s lifespan.

Surface Finishes to Maximize Equipment Life

Coatings and treatments represent the final step in the fabrication process, crucial for maximizing the lifespan of equipment. Heumann Environmental offers comprehensive expertise in surface protection strategies. Whether it’s mechanical polishing, passivation, or protective coatings, each finish is carefully selected to meet specific performance, compliance, and environmental demands.

Equipment Accessories & Options

Surface finishes are a critical way to customize industrial air filtration systems, offering enhanced protection against corrosion, wear, and contamination. Beyond surface finishes, we offer a wide range of customization options and accessories—ensuring your equipment is built for durability, simplified maintenance, and operational excellence. Explore your options below.