Precision Fabrication and Polishing for Biologic Drug Manufacturing

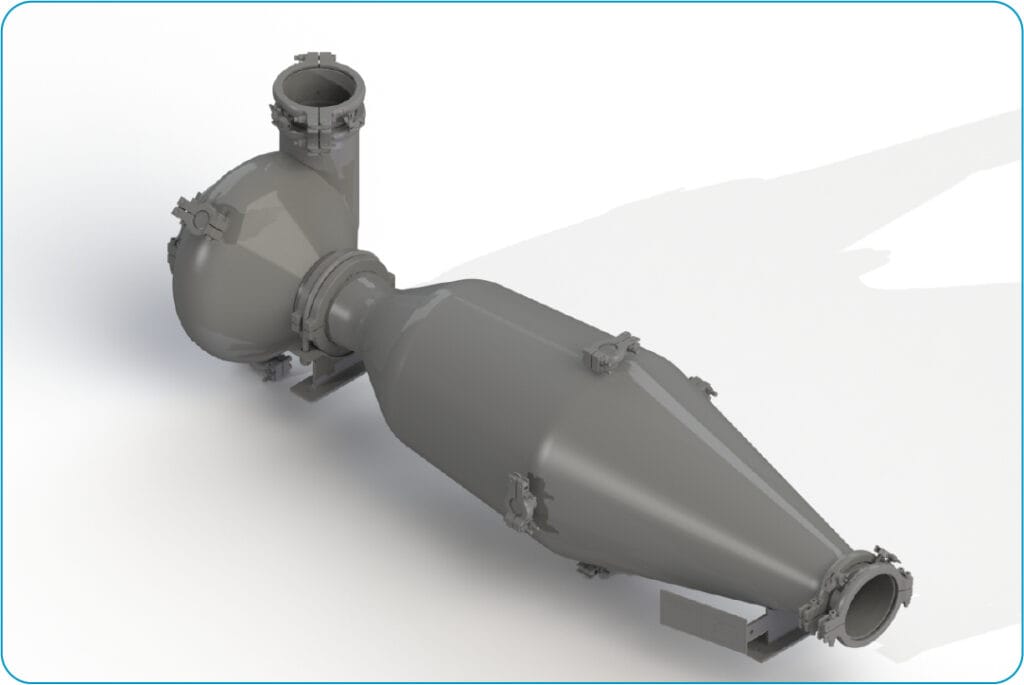

To meet the demanding standards of biologic drug manufacturing, a pharmaceutical client turned to Heumann Environmental Company (HEC) for a custom-engineered spray dryer system. The pressure vessel was ASME Code stamped, CE certified, and fabricated from SA-240 316 stainless steel with ultra-high surface finish and complex internal geometry, critical for both regulatory compliance and cleanability. Assembled section-by-section to allow internal access during polishing, the result is a precision-built, sanitary-grade system now actively supporting the production of widely used biologic medications.

A quick look or a comprehensive read—Download the case study below

Comprehensive breakdown with engineering insights, materials, and technical challenges.

Quick overview of the project, key specs, and outcomes.

The Challenge

Major advances in the development and introduction of a class of drugs called biologics has resulted in a large and rapidly growing demand for drugs of this type. Biologics are medications made from living organisms such as proteins or genes. These drugs, such as Humira, Enbrel, Breztri, and Tremfya, pose unique production challenges due to their susceptibility to spoilage and strict cleanliness demands.

Over the last decade, HEC has been involved in the development and supply of specialized spray drying systems coupled with ultra-high efficiency cyclone recovery systems for the commercial production of biologics and other popular pharmaceuticals.

In this case study, the pharmaceutical client sought out Heumann Environmental for our proven expertise in designing and fabricating ASME Code stamped and CE certified systems with complex geometries and elevated sanitary standards. While biologic manufacturing introduces a host of additional complexities beyond standard pharmaceutical production, this case study highlights a few of the critical challenges that made HEC the logical choice for this application.

Solution Provided

The system was designed and fabricated to accommodate pressures up to 145 psig in order to mitigate potential deflagration risk. It was ASME Code stamped and CE certified to this rating, with corresponding PED documentation. It posed unique challenges due to the exceptionally high polish required on both interior and exterior surfaces. The combination of ultra-smooth surface finish requirements and complex geometry demanded a uniquely tailored fabrication approach.

Key Spray Dryer System Features

System Specifications

Ensuring Sanitation in Inaccessible Spaces

All pharmaceutical systems must meet rigorous cleanliness standards with minimal cracks or crevices where product particles might accumulate, but biologics require even greater diligence. Because these drugs are derived from living organisms, their particles can decompose or spoil easily, increasing the risk of contamination between batches.

This means that systems run in batches of limited length to ensure that no “old” particles are present. To ensure product integrity, systems must be thoroughly cleaned between each production run. However, for this project, the physical size of the spray dryer openings made internal manual access impossible. In addition, flanges were not allowed in the sprayer body because of the potential for particle buildup and additional thermal mass that pressure-rated flanges would introduce, both of which would complicate both sanitation and performance.

This made it absolutely critical to achieve an exceptionally high surface finish and to adhere precisely to the complex design geometry. These challenges aligned perfectly with the capabilities and experience of our shop technicians, who are highly qualified for this level of sanitary fabrication.

Ultra-High Surface Finish Spray Dryer for Biologic Integrity

To exceed stringent cleanliness requirements, HEC polished all surfaces to Ra < 10 microinches, then applied a brief electropolishing process to passivate the stainless steel without removing additional material. The vessel was built from precision-machined, rolled, and spun components assembled from the inside out, ensuring full access for polishing prior to final closure.

The dryer was fabricated using a combination of sheet and plate-formed or rolled sections, custom metal-spun components, standard tri-clamp fittings, and precision-machined parts. Each component was assembled from the inside out, section by section, allowing internal surfaces to be fully polished before access was closed off. This approach ensured that all product-contact areas met strict cleanliness standards despite the vessel’s complex and enclosed geometry.

All work was performed in accordance with ASME Section VIII Division 1 and met CE testing, inspection, and certification standards.

Complex Shapes and Critical Geometry

The spray dryer’s original design had already been extensively validated through prototype testing, proving its ability to produce the precise particle characteristics required by the end user. Any deviation, however minor, risked altering its performance and would trigger the need for requalification through time-consuming and rigorous regulatory pathways and FDA approval.

To preserve both functional integrity and regulatory compliance, HEC replicated the original geometry exactly. Fabrication was executed section by section, ensuring that every contour matched the validated design and upheld the standards essential for biologic drug production.

Results and Outcomes

The successful delivery of this system highlights HEC’s uncommon ability to merge pressure vessel design and precision fabrication with the stringent sanitary and geometric requirements essential for biologic drug production. Few manufacturers possess the combined expertise in design, engineering, specialty fabrication, polishing, and quality assurance necessary to meet such demanding standards.

Today, the spray dryer is in active use, supporting the production of widely prescribed biologic medications. It’s highly likely that you, or someone you know, has benefited from a product manufactured using this very system.

Engineered for the Future of Biologics

This project showcases HEC’s proven ability to meet the dual demands of pharmaceutical sanitation and pressure engineering. It demonstrates that even highly complex systems can be fabricated with precision while maintaining strict cleanliness standards and reliable performance. As the biologics market grows, systems like this offer a model for scalable, compliant production in one of pharma’s most demanding sectors.

Beyond Off-the-Shelf: Precision Finish for Sanitary Standards

Meeting the sanitary and mechanical demands of biologic drug manufacturing requires more than standard fabrication. It demands precise control over surface finish to ensure product integrity, cleanability, and compliance. At HEC, every vessel is built through a collaborative, process-driven approach, with polishing performed by the same qualified technicians who handle fabrication. This ensures continuity, consistency, and strict adherence to the exact surface finish your application requires. Learn more about our surface finish capabilities ›

Explore More High TAPS Solutions

Our High TAPS capabilities span the full spectrum of process challenges—heat resistance, abrasive flows, pressure containment, and pharmaceutical-grade sanitation. We apply decades of experience to design and build systems that withstand daily extremes while maintaining regulatory compliance and long-term durability.

From biologic drug spray dryers to hydrocarbon separation cyclones, we deliver systems that work as hard as your process does.

Learn more about our High TAPS expertise and how we engineer solutions to thrive under the toughest conditions.