Equal Flow Rates Doesn’t Mean Equal Design

Comparing three high-efficiency cyclone systems, each with similar flow demands but vastly different thermal, pressure, and operational challenges

Comparing cyclone designs with matching ACFM rates reveals a critical truth: flow rate alone doesn’t define performance. These three projects, while serving different functions and operating under widely varying temperatures and pressures, all involved cyclone separators designed for similar ACFM flow rates. But that’s where the similarities end. Each system demanded a unique geometric configuration to perform effectively within its specific process conditions.

Plant managers looking to maximize the performance of high-efficiency separation equipment should ensure their cyclone designs are not one-size-fits-all, but rather precisely engineered to align with the thermal, pressure, and operational realities of their system.

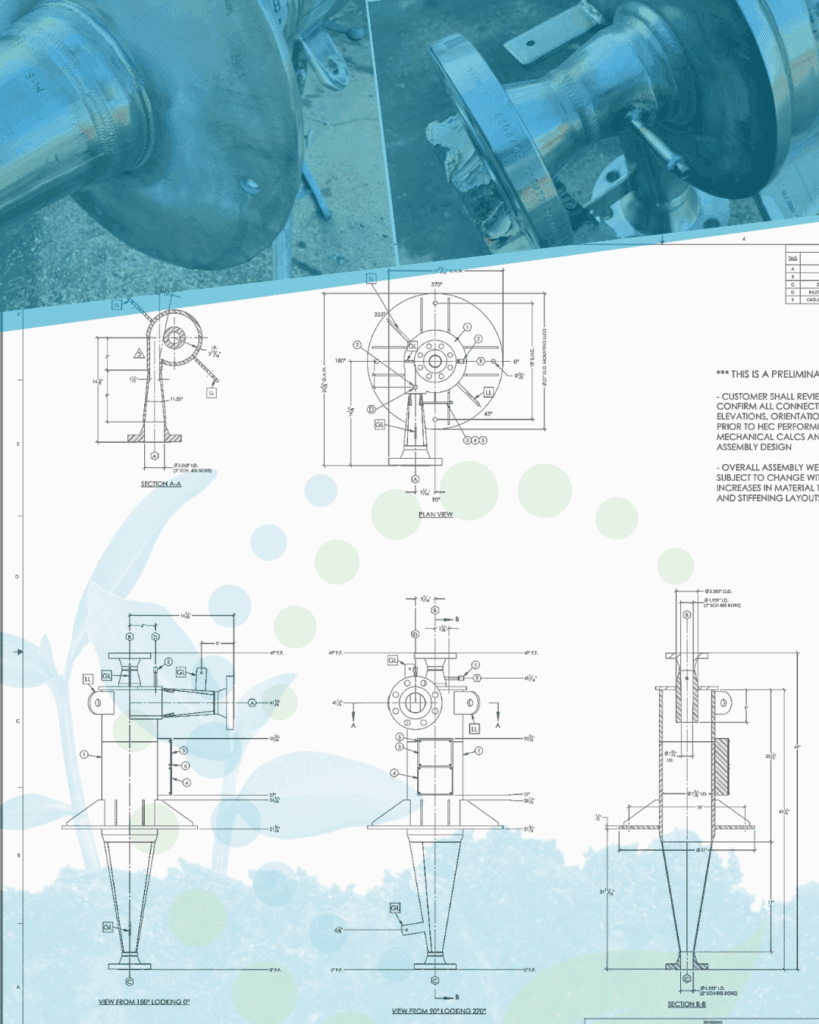

Fueling Clean Hydrogen Efforts with High-Pressure Cyclone Technology

The Challenge: C-Zero (now Graphitic Energy), was a pioneering startup in the green hydrogen sector. They required a reliable solution to separate carbon-based particulates from high-pressure process gas. Effective particulate removal was critical to enable downstream carbon sequestration, a key step in their clean hydrogen production from fossil fuel sources.

Strategy & Solution: HEC engineered a cyclone separator specifically rated for 580 PSI at 545°F, designed to operate seamlessly under extreme process conditions. This unit was integrated within a broader carbon capture system that also included two advanced baghouses, ensuring optimal filtration and system performance.

The Results: The full system was designed, fabricated, and brought online in approximately 12 months, supporting the launch of a novel green hydrogen process. The project met aggressive timelines while demonstrating our ability to execute complex, high-pressure systems critical to next-generation carbon capture.

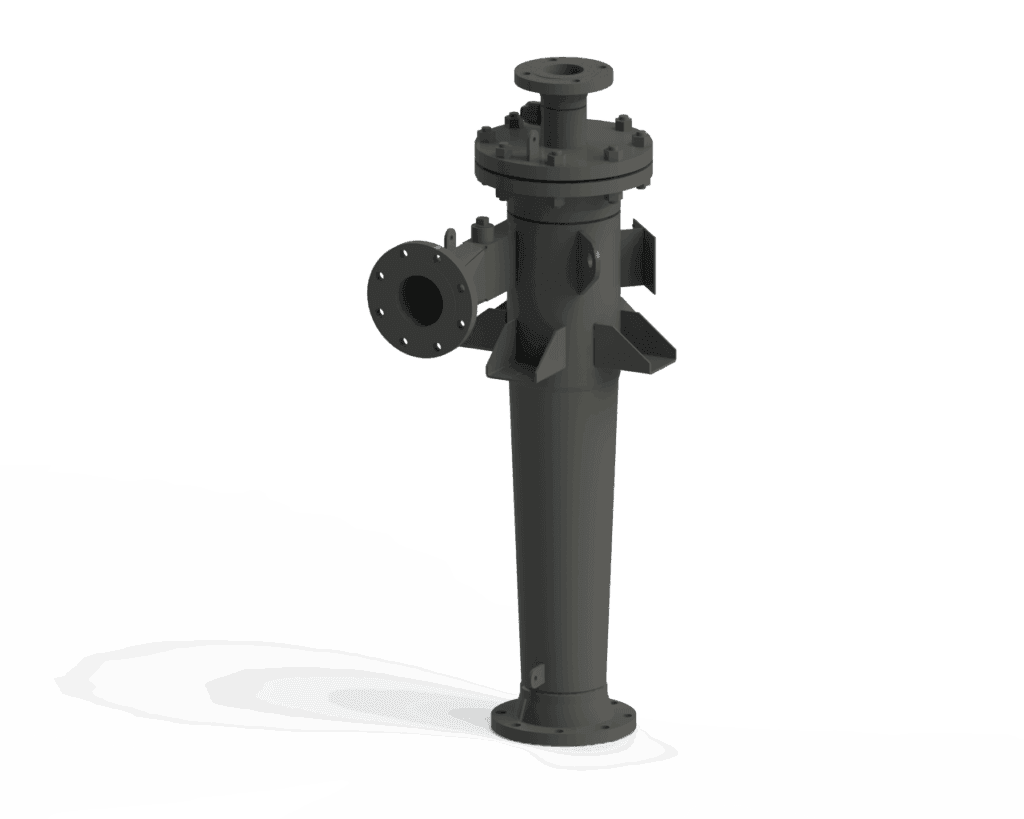

Optimizing biochar Recovery in High-Temperature Pyrolysis

The Challenge: Alleo Energy, a startup advancing renewable fuel production through biomass pyrolysis, required an efficient method to separate char from the process gas stream. Unlike many applications where solids are treated as waste, the char itself is the valuable end product, making recovery critical to operational success.

Strategy & Solution: We engineered a cyclone rated for 14 PSI at 752°F, incorporating a removable head design to allow internal access for cleaning and maintenance.

The Results: The project moved from design to delivery in approximately three months. As of Q1 2025, Alleo Energy’s test facility has been operating at full capacity, with the cyclone playing a key role in consistent and efficient fuel creation.

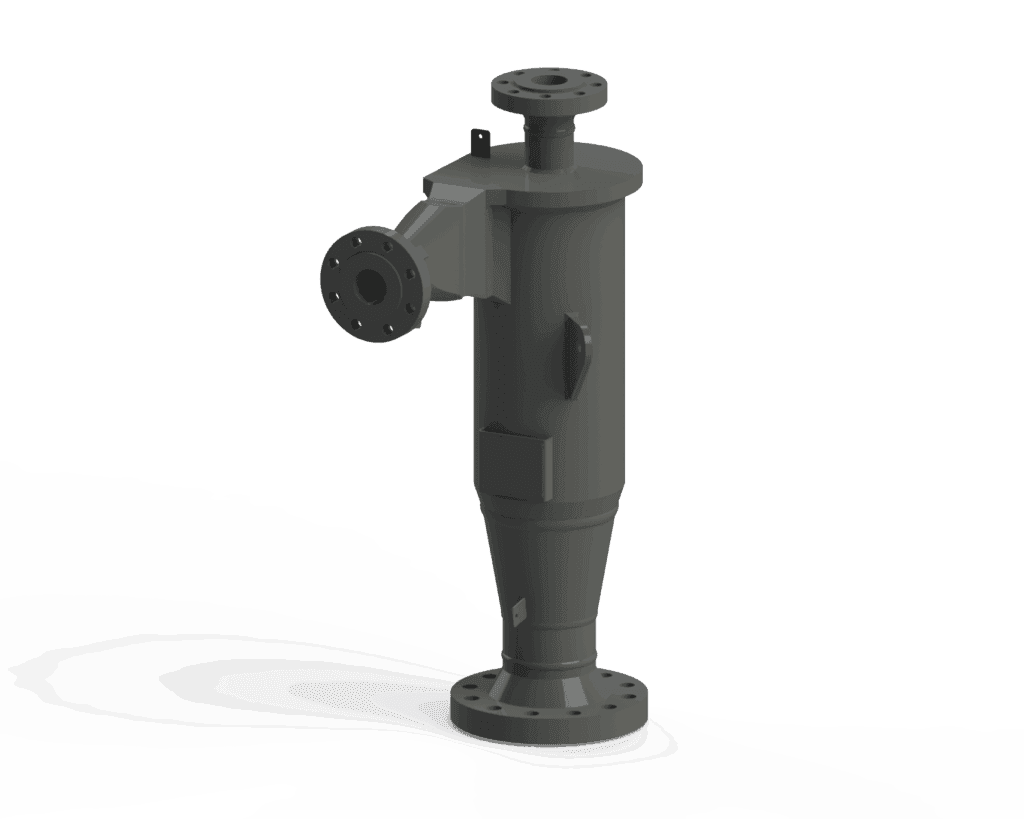

Pushing Thermal Limits in Clean Hydrogen Engineering

The Challenge: Building on the success of the previous project, C-Zero returned the following year with a new request for a cyclone separator serving another segment of their hydrogen system. Unlike the earlier unit, this one had to operate at substantially higher temperatures while still removing carbon-based particulates to support effective sequestration.

Strategy & Solution: Engineered to precisely match the thermal and pressure demands of this phase of their process, we designed a custom cyclone rated for 150 PSI at 1,382°F. This system required extensive verification against ASME Section VIII Division 1 Code to ensure structural integrity and suitability for the design temperature.

The Results: From the first technical discussions to final delivery, the project spanned approximately 18 months. The cyclone is now in operation at the pilot facility in Texas, where it supports ongoing testing and refinement of green hydrogen production.

Why Process Conditions Must Drive Cyclone Design

These three projects illustrate a key engineering principle: flow rate defines how much, but not how well. Cyclones operating at similar ACFM can, and should, look radically different when process conditions vary. Factors like high pressure, temperature, material abrasiveness, and maintenance access impose design constraints that standard geometries simply don’t address.

For plant managers and engineering teams, the takeaway is practical: start with your process parameters not just your flow specs. Geometry, materials, sealing, and access features must all align with the operational realities of your system. Done right, custom cyclone design isn’t added complexity, it’s engineered assurance.

A one-size-fits-all approach often leads to maintenance headaches, performance drops, and compromised ROI. Real cyclone design and performance depends on the combination of flow rates, pressure, temperature, and process dynamics.